Microsoft MB-335 Übungsprüfungen

Zuletzt aktualisiert am 27.04.2025- Prüfungscode: MB-335

- Prüfungsname: Microsoft Dynamics 365 Supply Chain Management Functional Consultant Expert

- Zertifizierungsanbieter: Microsoft

- Zuletzt aktualisiert am: 27.04.2025

HOTSPOT

Case Study

This is a case study. Case studies are not timed separately. You can use as much exam time as you would like to complete each case. However, there may be additional case studies and sections on this exam. You must manage your time to ensure that you are able to complete all questions included on this exam in the time provided.

To answer the questions included in a case study, you will need to reference information that is provided in the case study. Case studies might contain exhibits and other resources that provide more information about the scenario that is described in the case study. Each question is independent of the other questions in this case study.

At the end of this case study, a review screen will appear. This screen allows you to review your answers and to make changes before you move to the next section of the exam. After you begin a new section, you cannot return to this section.

To start the case study

To display the first question in this case study, click the Next button. Use the buttons in the left pane to explore the content of the case study before you answer the questions. Clicking these buttons displays information such as business requirements, existing environment, and problem statements. If the case study has an All Information tab, note that the information displayed is identical to the information displayed on the subsequent tabs. When you are ready to answer a question, click the Question button to return to the question.

Background

Fabrikam Inc. is a manufacturer of sanitation cleaning solutions and equipment including carpet/floor cleaners, pressure washers, scrubbers and vacuums.

Fabrikam Inc. is a single legal entity based in New York city.

_ Current environment

Products manufactured

• Cleaning equipment o floor cleaner

o pressure washers o scrubbers

o vacuums

• Liquid cleaning solutions o No scent

o Orange scent (subcontracted to a vendor named Vendor A)

o Pine scent (subcontracted to a vendor named Vendor A)

The production quantity for the finished unscented liquid cleaning solution is 40-liters. Ingredient C ‚or unscented liquid cleaning solution Is stored in inventory in 50-liter barrels and allocated in 50-liter increments. Two barrels of Ingredient C are uses to produce a barrel of unscented liquid cleaning solution.

Production sites

• The Eastern United States facility manufactures equipment.

• The Western United States facility manufactures liquid cleaning solutions.

• Raw materials and finished products are stocked at the warehouse and distributed from the warehouse.

Warehouse facilities

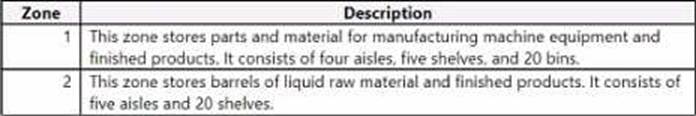

The warehouse consists of the following zones:

_ Requirements

Cleaning equipment manufacturing

You identify the following require merits for manufacturing cleaning equipment:

• Production is Make to Stock and must be scheduled at an operational level.

• Machine equipment is produced on an assembly line. Scheduling must be based on production orders.

• Finished products must be packaged and shipped directly from the warehouse.

• To reduce delivery times and excess inventory, equipment must be produced as needed.

• The ability to schedule production must be based on resource capacity and the availability of required materials.

• Production order operations must be scheduled to start only when capacity and materials are available at the same time and in the required quantities.

Liquid cleaning solution manufacturing

• Production is Make lo Order and is scheduled at the job level. Products must be manufactured in batches.

• Finished products must be packaged and shipped directly from the warehouse.

• You must be able to calculate the estimated consumption of ingredients and ensure that the

amount is divisible by the number of units the raw material «s available.

• Formula changes must be reviewed and approved. You must ensure that approved formulas cannot be deleted or edited. Approved formulas may be deactivated.

• An ingredient used to manufacture unscented cleaning solution is defined as a restricted product. You must be able to automatically print a product safety data sheet (PSDS) with the packing slip for any order that includes unscented cleaning solution.

• Production must be scheduled to start by date and time according to the order that is specified by the production route.

• You must implement a scheduled Kanban rule that meets the following requirements:

o Prevent overloading a work cell for scheduled Kanbans. o Visualize excess inventory in a supermarket.

o Store products in supermarkets before they are consumed or shipped.

• You must link relevant financial dimension data to the inventory transactions at each site to ensure that you can trace profit and loss figures directly to East site and West site respectively.

• You must set up production operations for sub-contracting of Pine scent and Orange scent solution to Vendor A to ensure that a purchase order is automatically created based on estimation of a production order.

Costing

• The price of raw materials used for manufacturing unscented cleaning solution must be tracked based upon commodity exchange pricing. The margin and cost multiplier must be set up for commodity traded raw material.

• You must set up cost calculation groups to ensure that indirect costs that originate in the manufacturing of finished goods are recognized and absorbed into the product cost.

• The production manager needs to set up picking list journals and BOM item consumption.

Reporting

• Production control parameters must be setup for reporting of automatic BOM and Route consumption.

• You must create reports that include information about cost records and categories for items, and calculation formulas for indirect costs.

• You must treat manufactured items as purchased items for cost roll-up purposes during BOM calculations and reporting.

• You must configure automatic route consumption in connection with the automatic running of Report as finished.

Inventory control

You must not be required to track the tot number for items when you enter inventory information into the system. Lot numbers for items must be entered when items are picked from inventory.

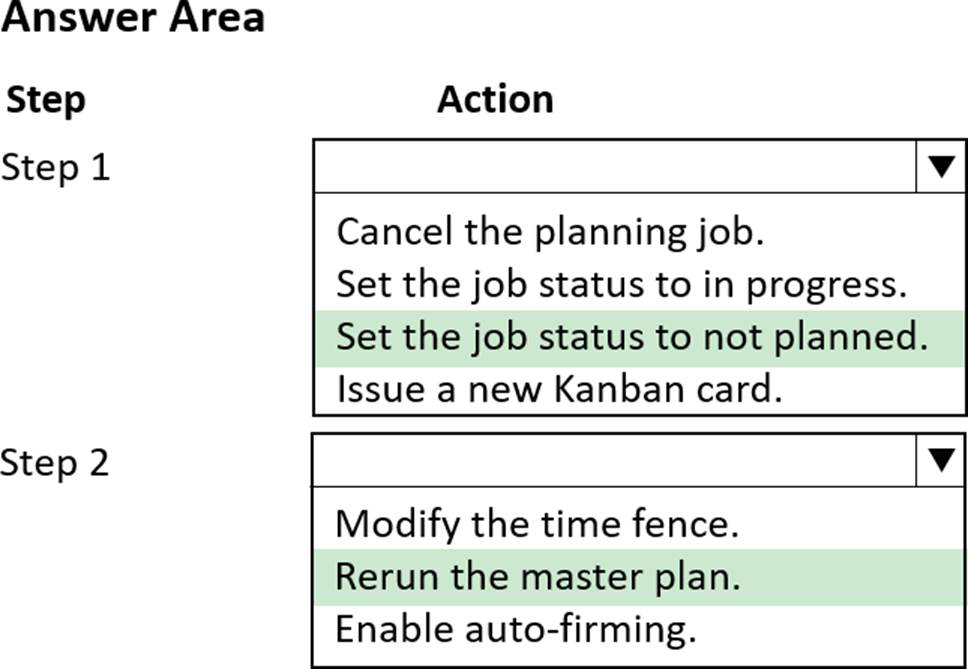

Issues

Users report the following issues:

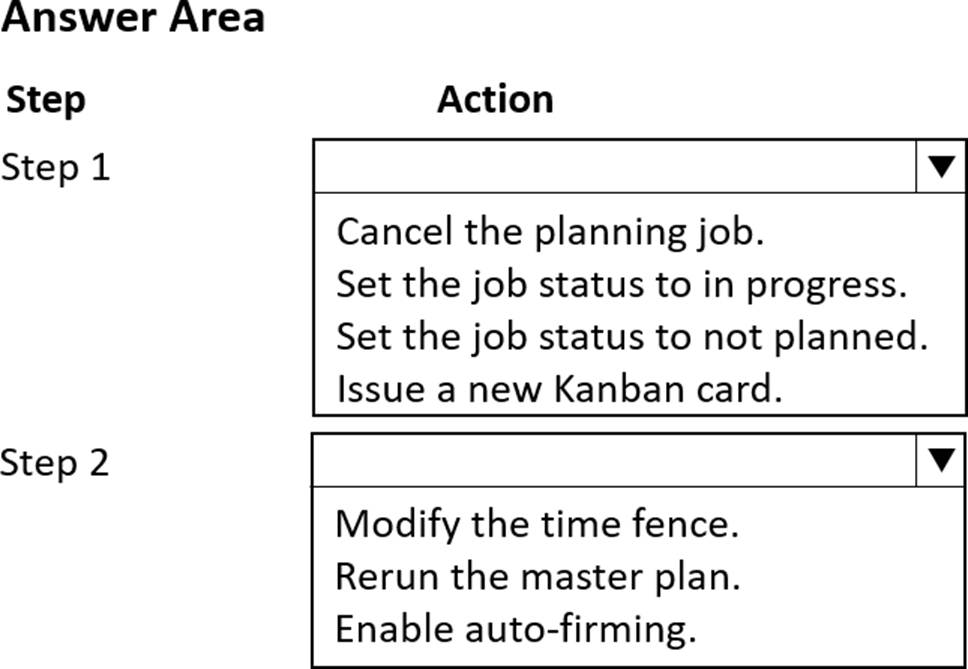

• The production manager observes that items are being deducted from inventory two times on production jobs. A shop supervisor mistakenly registers the process for assembling batteries for the pressure washers to Registered as prepared. You must reschedule the process for a future date.

• Customer1 orders 20 barrels of unscented solution. The order is confirmed. Production must be scheduled to start on December 21 to meet the customer’s delivery deadline.

• User2 reports that costs for manufactured items are twice as high as expected.

• User 1 reports that the formula for the liquid cleaning solution sometimes changes during production. You must enforce the policies regarding formula editing for current and future use.

You need to resolve the shop supervisor’s issue.

Which options should you use? To answer, select the appropriate options in the answer area. NOTE: Each correct selection is worth one point.

A beverage company uses Dynamics 365 Supply Chain Management batch processing for production.

You need to identify the ingredient type used in batch processing when the base attribute of a product is added to a formula line.

What is the ingredient type?

- A . active

- B . compensating

- C . filler

- D . none

A company uses engineering change management in Dynamics 365 Supply Chain Management. The Product readiness checks feature is turned off.

An existing engineering product must be reconfigured for a new product readiness policy.

You need to change the product readiness policy.

Where should you make this change?

- A . default order settings

- B . shared product

- C . engineering category

- D . product configuration model

- E . released product

You are a production manager at a company which produces large batches of coffee and creamers.

After a quality inspection, batch 120008 of your cold brew coffee (item number CB-0001) was found to be too acidic and must be reworked.

You need to add 20 grams of sugar and stir the product for an additional 0.5 hours.

What three actions are required on the rework order? Each correct answer presents part of the solution. NOTE: Each correct selection is worth one point.

- A . Manually reserve batch 120008 after estimating the batch order.

- B . Add a route operation for 0.5 run time hours of stirring.

- C . Add 20 grams of sugar to the production formula.

- D . Delete all items from the production formula except for 20 grams of sugar.

- E . Delete all route operations except for a half an hour stirring operation.

A company plans to use master planning in Dynamics 365 Supply Chain Management. The company will sell items between legal entities.

The company has several facilities across legal entities that can manufacture the same products. Same products are produced only in some plants. To meet product demand, when one facility is over capacity, another facility is used to fulfill the downstream demand.

The organizational entities are:

• LegalEntityA: Plant 1.2, and 3

• LegalEntityB: Plant4and 5

• LegalEntityC: Plant 6. 7, and 8

The following plants must be planned together:

• Plant 1. Plant 3. and Plant 4

• Plant 2. Plant 6. and Plant 8

• Plant 5 and Plant 7

You need to configure master planning for the facilities.

Which configuration mechanism should you use?

- A . Production groups

- B . Item model groups

- C . Coverage groups

- D . Intercompany planning groups

HOTSPOT

Background

Adatum Corporation is a multi-entity corporation located in Seattle, Washington in the United States. The company is a leading producer of specialty cakes and cookies. The company also manufactures specialty chocolates that use ethically sourced ingredients from around the world. The company plans to launch a new product line of organic chocolates later this year.

Adatum plans to implement Dynamics 365 Finance and Dynamics 365 Supply Chain Management to

manage financials, inventory, and manufacturing capabilities across the entire organization.

Current environment. Distribution

• Manufactured products are stored at the distribution warehouses until they are shipped to customers.

• Individually branded pre-packaged cake and cookie mixes are supplied to specialty cafes and restaurants. The mixes are shipped directly to the cafes and restaurants from the production factories.

• The company maintains a fleet of trucks and also subcontracts shipments between the factories and warehouses to outside vendors.

Current environment. Production

• The mixes and specialty chocolates are based on standard recipes that use precise ingredient ratios. There are strict rules around ingredient substitutions.

• All mixes use one of three base recipes as their foundation: BaseA, BaseB. and BaseC. Additional ingredients, spices, and flavorings are then added to make the final product.

• BaseA and BaseB are made in large batches and stored until they are used in the other mixes.

• Mixes with BaseA have a shelf life of six months due to the type of flour it uses.

• Specialty chocolates are manufactured only during the holiday season.

• Specialty desserts are offered during the holiday season. This year, customers may specify additional icing colors and cake layers when placing orders. Depending on the popularity of two of the new colors, they may be offered the next year.

• Cocoa oil that is extracted during the production of some of the specialty chocolates is used in the BaseB foundation mix.

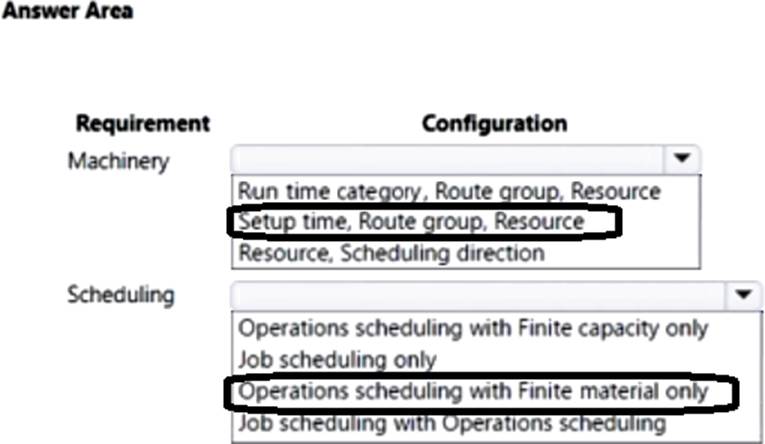

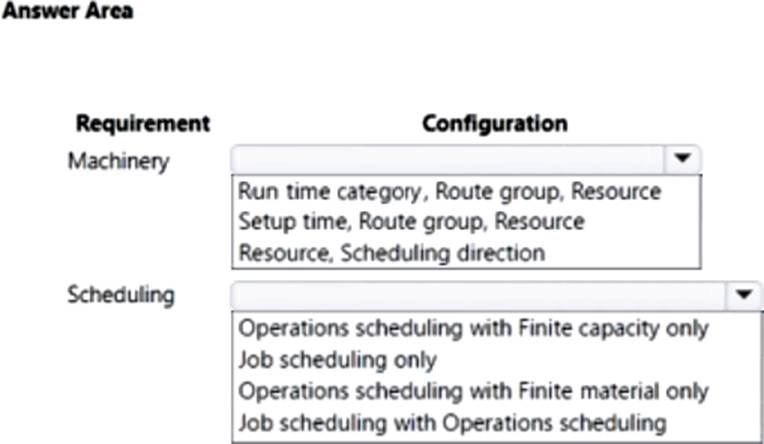

• Cleaning and setup of machinery between products has been causing delays in production.

• Prices of raw ingredients such as sugar can fluctuate greatly depending on seasonal and worldwide demand.

• To properly record profitability, ail raw materials use the first in, first out (FIFO) costing method, while finished products are recorded at standard costs.

• Large fluctuations have been occurring at month end in costs reported due to the inability to track production runs that span from month-to-month.

• Leftover flour and sugar from production runs are collected, packaged, and donated to local food banks if the amount is too small to use in other runs.

Requirements. Production

• To maintain Adatum’s certification as a manufacturer of ethically sourced ingredients, the traceability of every ingredient in all products to their source must be tracked.

• All products must be randomly tested for adherence to quality standards for ingredient makeup and weight.

• Similar recipes must be able to be produced in succession to limit machinery cleaning and setup times.

• All costs must be tracked for each production run and be able to be reconciled at the end of the monthly accounting cycle, including any work in process (WIP) costs and donations.

• The organic chocolate line must be set up. The ingredients cannot be mixed with non-organic ingredients in inventory.

Requirements. Warehouse

• Mixes are generally stored and sold in 16-ounce bags. Some quantities are sold and distributed in 5. 10. and 20-gallon containers to large restaurants.

• Each mix has a single unique item number and is tracked per batch produced.

• Specialty chocolate products must be stored in climate-controlled areas of the warehouse.

Issues

• QA TesterA discovers during a random test that the batch of a mix does not contain the necessary amount of IngredientB.

• VendorZ, who transports finished goods from PlantA to Warehouses, is consistently late picking up product.

• OperatorA must consolidate partial mix batch group runs into saleable package quantities.

• UserB must set up the mix items.

• UserC learns that mixes containing BaseA have been stamped with a batch date from the flour vendor and is not being calculated from the mix manufacturing date. The mixes from the past month that might be impacted need to be identified and the calculation needs to be corrected.

• UserD must update the costs of finished goods. Accounting wants labor calculated in WIP based on how much time an individual spends performing the operation, as well as the finished goods to post to a specific different ledger account.

• UserE must set up and maintain the cost of sugar.

• UserF must decrease downtime for the machinery.

• UserG must plan the specialty desserts for the current holiday season.

You need to resolve the issue for UserF.

What should you configure? To answer, select the appropriate options in the answer area. NOTE: Each correct selection is worth one point.

You work for a gem wholesaler that sells raw diamonds. Diamonds are purchased and sold in individual boxes but weighed and inventoried in carats.

You are setting up a catch weight item for diamonds. Each box of diamonds must be tracked by its individual container weight.

You need to set up this item as a full visibility catch weight item.

Which two steps must you perform? Each correct answer presents part of the solution. NOTE: Each correct selection is worth one point.

- A . Assign the item a Tracking dimension group with active serial number control

- B . Assign it a Serial number group with per qty. defined as 1.

- C . Assign a Tracking dimension group with batch number as the only active tracking dimension.

- D . Create an inter-class unit of measure conversion between boxes and carats.

Note: This question is part of a series of questions that present the same scenario. Each question in the series contains a unique solution that might meet the stated goals. Some question sets might have more than one correct solution, while others might not have a correct solution.

After you answer a question in this section, you will NOT be able to return to it. As a result, these questions will not appear in the review screen.

A manufacturing company produces electronic components and devices.

The company has scheduling issues related to using working time calendars in manufacturing.

You need to ensure that the working time calendar is used when manufacturing jobs are scheduled.

Solution: Disable route groups for a process job type.

Does the solution meet the goal?

- A . Yes

- B . No

Note: This question is part of a series of questions that present the same scenario. Each question in the series contains a unique solution that might meet the stated goals. Some question sets might have more than one correct solution, while others might not have a correct solution.

After you answer a question in this section, you will NOT be able to return to it. As a result, these questions will not appear in the review screen.

A manufacturing company produces electronic components and devices.

The company has scheduling issues related to using working time calendars in manufacturing.

You need to ensure that the working time calendar is used when manufacturing jobs are scheduled.

Solution: Disable route groups for a process job type.

Does the solution meet the goal?

- A . Yes

- B . No

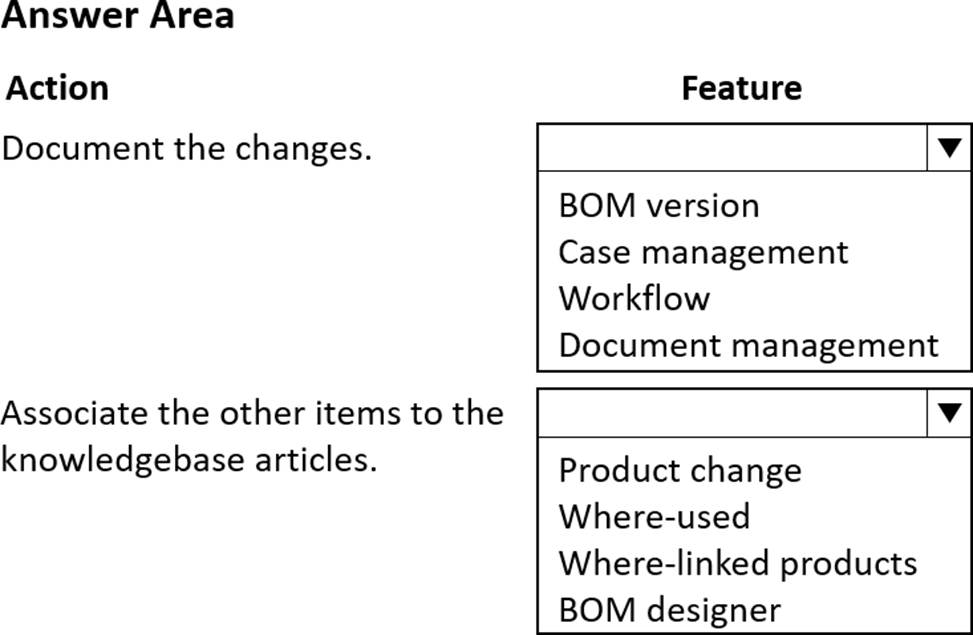

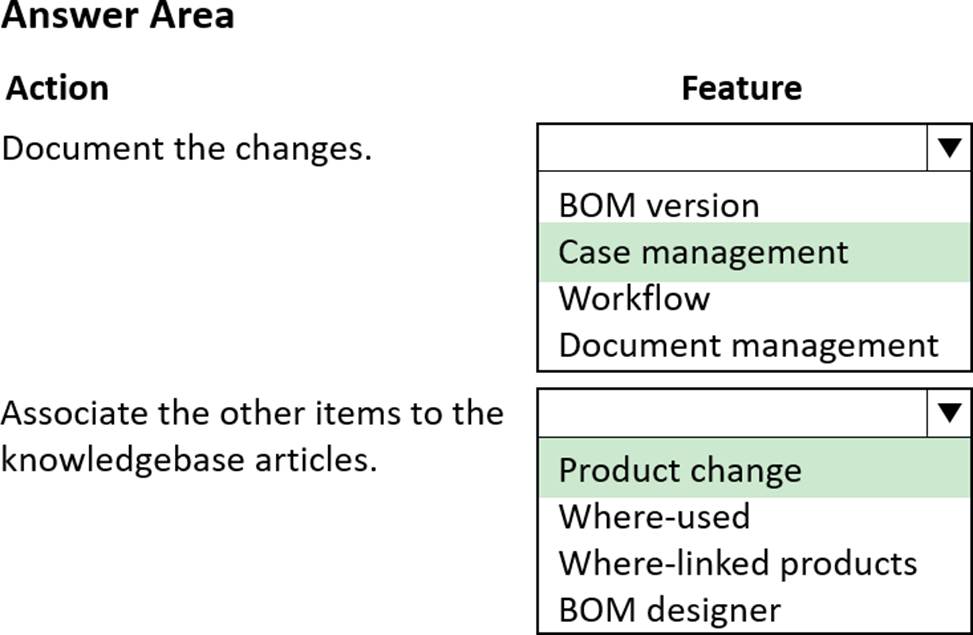

HOTSPOT –

A manufacturing company uses Dynamics 365 Supply Chain Management.

The company identifies a bill of materials (BOM) item that needs to be recalled for a product.

The engineering department needs to link customer support incidents and knowledgebase articles related to the product change.

Other items affected by this change must reference the same support incidents and knowledgebase articles.

You need to recommend features to facilitate this business process.

Which features should you recommend? To answer, select the appropriate options in the answer area. NOTE: Each correct selection is worth one point.